There are currently two technical schools of energy storage connectors, one is the quick plug method, and another is the copper row connection. From the point of view of several internationally renowned connector manufacturers' products, basically are pushing fast plug this technology. But the choice of this technology school, but also benevolent and wise.

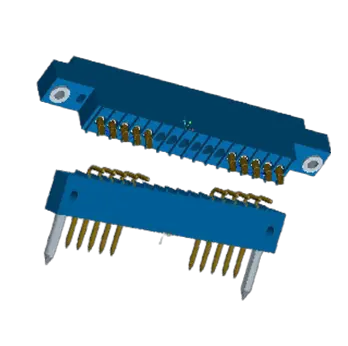

Copper row connection is a soft connection, copper row soft connection of the lap interface using molecular diffusion welding technology one-time welding molding, strong electrical conductivity, the ability to withstand the current is relatively large, in the high current connection does have advantages. And more crucially, the consistency of the copper strip connection may be better in comparison to the technical aspects alone. Possible is used here, because even the well-known international leaders in energy storage connections cannot guarantee that consistency will be maintained within a fixed range in a system with a dense accumulation of connections. Of course, the installation and maintenance costs associated with this method of connecting copper rows are also much higher than those of quick-plug, requiring manual on-site installation and not being as safe as they could be without protection against electric shock.

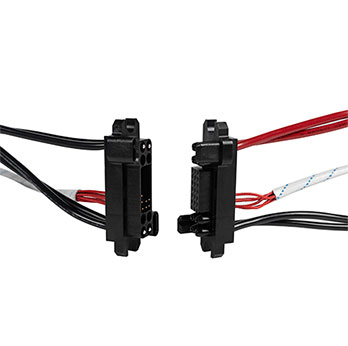

The quick-plug technology offers more advantages, first of all the protection against electric shock, which is clearly defined in the latest UL4128 standard for static energy storage systems. The positive and negative terminals of the quick plug also increase the safety of the connected devices and are structurally much safer than copper connections. The ease of installation goes without saying, but the cost of the equipment is naturally higher. Weak consistency is a problem that can not be avoided by fast plug technology, in the structure of the terminal part of the design of the inherent structural aspects of the decision it is slightly weaker consistency, and fast plug technology in the design process must be enlarged margin, the consistency of the connection resistance is not possible without fluctuations, the specific degree of consistency can be achieved depends on the technical strength of the manufacturers.

Quick-insert technology generally gives the connector sufficient swivel angle to facilitate quick installation while further saving wiring space and facilitating multi-directional wire exit. To further improve safety during installation, visual locking control mechanisms and finger protection contacts can be added; to ensure the accuracy of the connection process, effective mechanical coding systems are also incorporated into the connectors. The time and cost savings achieved through quick plugging are well worth the effort.